In today’s digital era, information technology (IT) has become an essential part of all businesses, irrespective of their industry. One sector that’s rapidly embracing IT is manufacturing. Manufacturing firms are increasingly looking towards IT outsourcing as a means to improve productivity, reduce costs, and remain competitive. This blog explores the impactful role of IT outsourcing on the productivity of manufacturing companies.

Streamlining Operations

Manufacturing is a process-intensive industry that involves a multitude of activities such as inventory management, procurement, production, and logistics. An outsourced IT service can help in streamlining these operations by implementing and managing robust Enterprise Resource Planning (ERP) systems. ERPs integrate various business processes into a single system, improving coordination, reducing errors, and increasing efficiency. This translates to a tangible increase in productivity.

Harnessing Data for Operational Excellence

Modern manufacturing generates enormous amounts of data – from shop floor machines, supply chain operations, quality control, and more. Managed IT services can assist in the collection, storage, and analysis of this data. By leveraging big data analytics and machine learning, companies can gain valuable insights into their operations, identifying bottlenecks, predicting maintenance requirements, and optimizing resource utilization. Thus, informed decision-making based on these insights significantly boosts productivity.

Enhancing Supply Chain Management

The manufacturing industry is heavily reliant on efficient supply chains. Outsourced IT services can improve supply chain management through the implementation of advanced IT solutions such as inventory management systems, tracking tools, and predictive analytics. These tools offer real-time visibility into the supply chain, enhance coordination among various stakeholders, and help in demand forecasting. As a result, companies can reduce delays, manage inventory effectively, and adapt swiftly to changes, thereby enhancing productivity.

Boosting Cybersecurity

In a manufacturing context, a cybersecurity breach could mean more than just data loss – it can result in downtime, which directly impacts productivity. An outsourced IT service provider with expertise in cybersecurity can help protect critical infrastructure from threats. From securing network perimeters and installing firewalls to conducting regular audits and providing disaster recovery solutions, these services play a crucial role in minimizing downtime and keeping the production lines running smoothly.

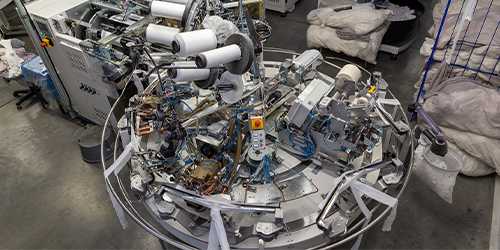

Facilitating Industry 4.0 Adoption

Industry 4.0, or the fourth industrial revolution, embodies the integration of digital technologies like IoT, AI, and cloud computing into manufacturing. Adopting Industry 4.0 can significantly boost productivity by enabling automation, real-time monitoring, and smart decision-making. However, transitioning to Industry 4.0 can be complex and requires significant IT expertise. Outsourced IT providers can facilitate this transition, offering the necessary technological infrastructure, expertise, and support.

Ensuring IT System Uptime

Downtime of IT systems can disrupt manufacturing processes, leading to delays and losses. Managed IT service providers ensure the regular maintenance and updating of systems, provide round-the-clock monitoring to detect and fix issues proactively, and offer reliable tech support. This continual upkeep and support ensure the smooth operation of IT systems, contributing to uninterrupted manufacturing processes and thus, higher productivity.

In conclusion, IT outsourcing can have a significant positive impact on the productivity of manufacturing companies. By streamlining operations, leveraging data for operational excellence, enhancing supply chain management, boosting cybersecurity, facilitating Industry 4.0 adoption, and ensuring IT system uptime, outsourced IT services can act as a catalyst for increased productivity and efficiency in the manufacturing sector.